|

| Figure 1. Piston and connecting rod |

I decided to share this assembly of a piston with connection rod now, as this is a part of my bigger project.

A piston is a component of reciprocating engines, reciprocating pumps, gas compressors and pneumatic cylinders, among other similar mechanisms. It is the moving component that is contained by a cylinder and is made gas-tight by piston rings.

In an engine, its purpose is to transfer force from expanding gas in the cylinder to the crankshaft via a piston rod and/or connecting rod.

In a pump, the function is reversed and force is transferred from the crankshaft to the piston for the purpose of compressing or ejecting the fluid in the cylinder.

1. Parts of assembly

- Piston crown and piston skirt

- Piston rings

- Wrist pin

- Snap (retaining rings)

- Connecting rod shaft and cap (with bushings - plain bearings)

|

| Figure 2. Parts of assembly |

1.1. Piston crown and piston skirt

The Piston comprises of two pieces; the crown and the skirt. The crown is subject to the high temperatures in the combustion space and the surface is liable to be eroded/burnt away. For this reason the material from which the crown is made must be able to maintain its strength and resist corrosion at high temperatures. Steel, alloyed with chromium and molybdenum is used, and some pistons have a special alloy welded onto the hottest part of the crown to try and reduce the erosion caused by the burning fuel. The crown also carries the 4 or 5 piston ring grooves which may be chrome plated.

The cast iron skirt acts as a guide within the cylinder liner. It is only a short skirt on engines with an exhaust valve (known as uniflow scavenged engines), as unlike a trunk piston engine, no side thrust is transmitted to the liner (that's the job of the crosshead guides).

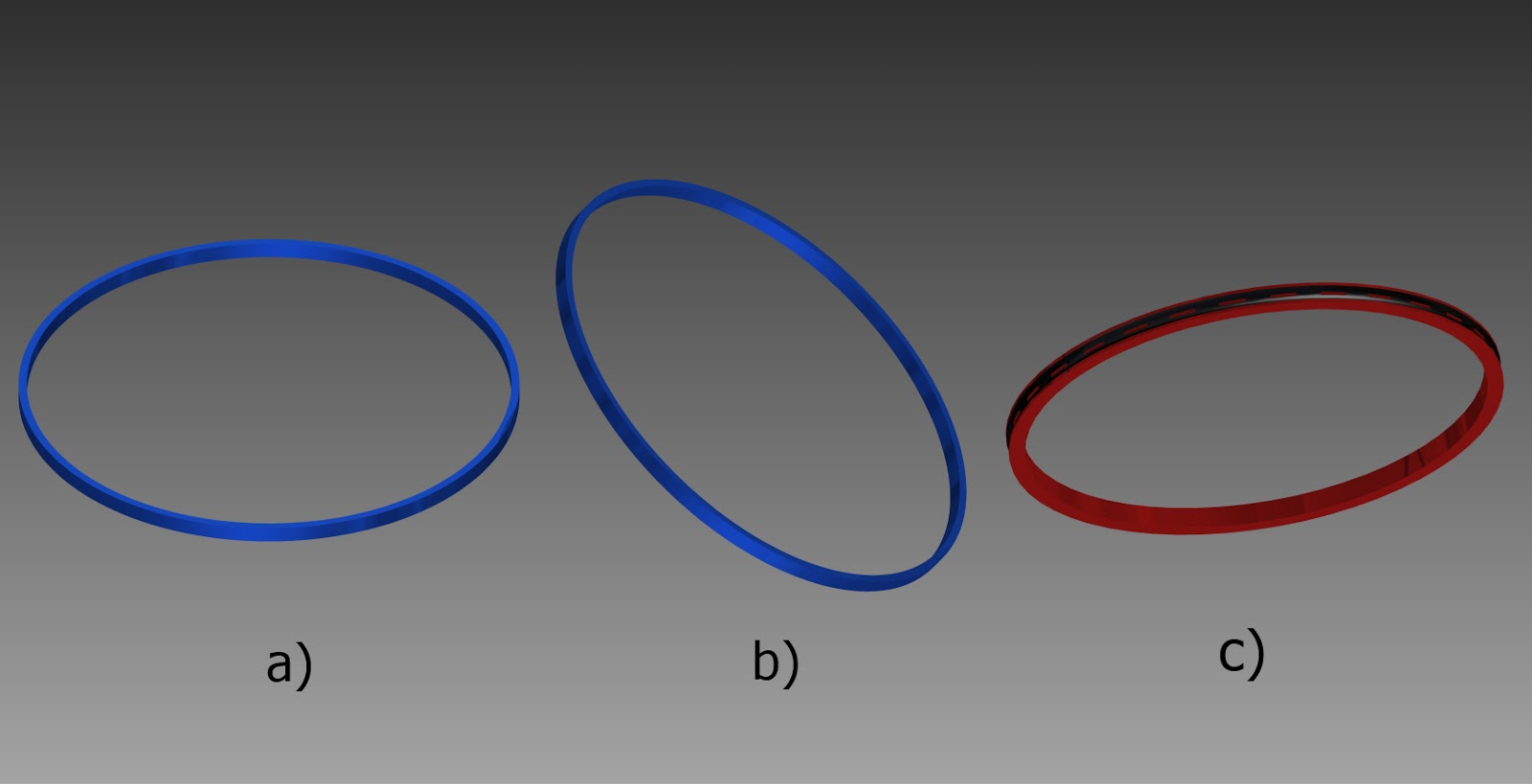

1.2. Piston rings

A piston ring is a split ring that fits into a groove on the outer diameter of a piston in a reciprocating engine such as an internal combustion engine or steam engine.

The three main functions of piston rings in reciprocating engines are :

- Sealing the combustion/expansion chamber.

- Supporting heat transfer from the piston to the cylinder wall.

- Regulating engine oil consumption.

The gap in the piston ring compresses to a few thousandths of an inch when inside the cylinder bore. Most automotive pistons have three rings: The top two while also controlling oil are primarily for compression sealing (compression rings); the lower ring is for controlling the supply of oil to the liner which lubricates the piston skirt and the compression rings (oil control rings). At least two piston rings are found on most piston and cylinder combination.

|

| Figure 3. a) Top compression ring, b) Second compression ring and c) Oil control ring |

1.3. Wrist pin and snap rings

The connecting rod is attached to the piston by a swivelling gudgeon pin (US: wrist pin). This pin is mounted within the piston.

A retaining (snap) ring is a fastener that holds components or assemblies onto a shaft or in a housing/bore when installed in a groove. Once installed, the exposed portion acts as a shoulder which retains the specific component or assembly.

Self-locking retaining rings may be installed in applications where no groove exists.

Retaining rings are typically made from carbon steel, stainless steel or beryllium copper and may feature a variety of finishes for corrosion protection depending on the type of environment in which they are used.

|

| Figure 4. Wrist pin and snap (retaining rings) |

1.4. Connecting rod shaft and cap (with bushings - plain bearings )

In a reciprocating piston engine, the connecting rod or conrod connects the piston to the crank or crankshaft. Together with the crank, they form a simple mechanism that converts linear motion into rotating motion.

Connecting rods may also convert rotating motion into linear motion. Historically, before the development of engines, they were first used in this way.

A plain bearing is the simplest type of bearing, comprising just a bearing surface and no rolling elements. The simplest example of a plain bearing is a shaft rotating in a hole. Plain bearings, in general, are the least expensive type of bearing. They are also compact and lightweight, and they have a high load-carrying capacity.

A bushing, also known as a bush, is an independent plain bearing that is inserted into a housing to provide a bearing surface for rotary applications; this is the most common form of a plain bearing.

|

| Figure 5. Connecting rod shaft (with bearings) |

No comments:

Post a Comment